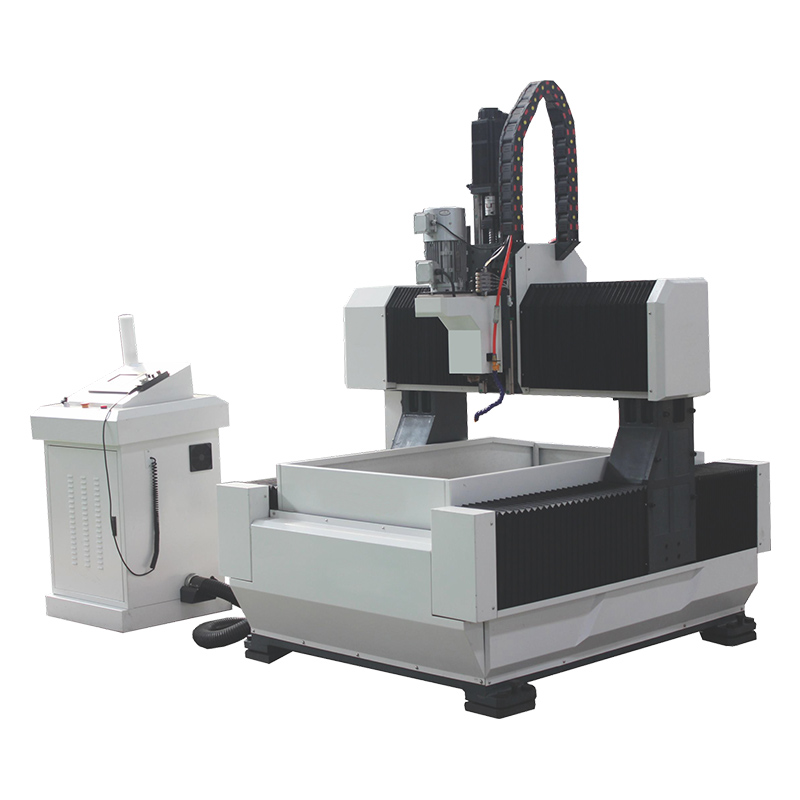

Technical Parameters of Equipment

| 1 | Material Cutting Range | Φ15-Φ70 (Bigger Specification Can be Customized) |

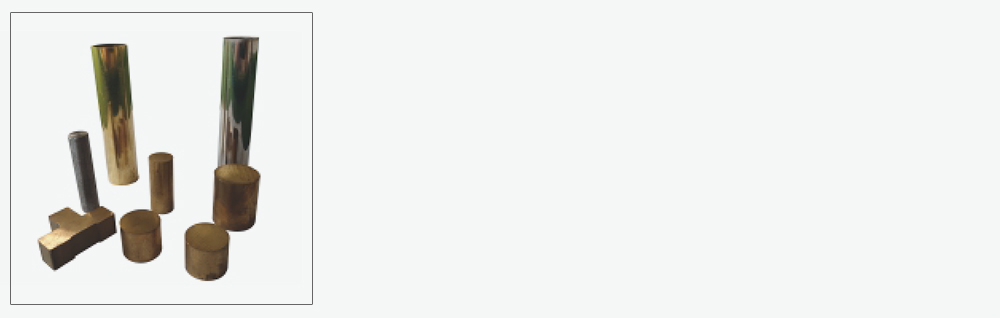

| 2 | Suitable Materials | Copper Rod,Copper Pipe,Aluminum Pipe and Steel Pipe |

| 3 | Blade Feeding Method | Servo Feeding |

| 4 | Blade Feeding Method Blade Cutting | 15-3000RPM |

| 5 | Matering Entering Method | Materials Sending of Servo(Without Relying Tooling) |

| 6 | Blade Specificationand Type |

1、HHS-DM05 220×1.2Teeth Number 108 2、HHS-DMO5 250X1.5Teeth Number 120 |

| 7 | Clamping Method | Hydraulic Clamping |

| 8 | Cutting Velocity(Based on Φ25) | 1.5 seconds per piece, 20,000piece per class(with 8 hours) |

| 9 | Cutting Accuracy |

1、Length Accuracy ±0.05mm 2.Section Verticality ±0.05mm |

| 10 | Working Gas Pressure | 0.4~0.6Mpa |

| 11 | Hydraulic Working Pressure | 5Mpa |

| 12 | Equipment Power |

1、General Power 11Kw, 2、Main Electric Motor Power 5.5Kw |

| 13 | Equipment Dimension(L*W*H)mm | 6000×1900×1600 (With 4.2Meters of Material Bracket) |

| 14 | Lathe Weight | About 1.8T |

| 15 | Degree of Automation | Bundles of copper rods are loaded,automatically lifted, divided, replenished and automatically changed into one box of materials. |

| 16 | Head and Tail of Materials | Head of material is adjustable by 5mm,and tail is 25+ cut length,Head and tail of material are automatically separated into the specified box. |

| 17 | Auxiliary Function |

1.Knife Wear Warning; 2.Knife Cooling Self-lubricating; 3.Automatic Copper Scrap Collecting Container Bag; 4.Set Function of Material Downloading, Blade Diameter Entering, Blade Width, Material Diameter, and Length of Material Downloading. |

One-shot product

Phone:+86-13588590265

Phone:+86-13588590265 E-mail:

E-mail: